AIRLIFT BIOREACTOR

AIRLIFT BIOREACTOR

TEC-BIO-P-30-AIR-LIFT

Used for: Fermentations and Bioprocesses Cultivation of animal cells and OM (bacteria fungi and yeasts) Enzymatic and Acid Hydrolysis Biomass Biofuels and 2G Ethanol Enzyme Production Vaccines and Drugs Biological Control Bioinoculants and Biofertilizers Bioremediation and Waste Treatment Studies in Mining and Bioleaching of Ores Production of oils creams and cosmetics and Chemical reactions.

Sugar & Ethanol

Sugar & Ethanol

Food, Beverage & Animal Nutrition

Food, Beverage & Animal Nutrition

Environmental, Waters & Effluents

Environmental, Waters & Effluents

Plant & Soil Science

Plant & Soil Science

Pharmaceutical & Cosmetics

Pharmaceutical & Cosmetics

Microbiology & Biotechnology

Microbiology & Biotechnology

Chemistry & Petrochemicals

Chemistry & Petrochemicals

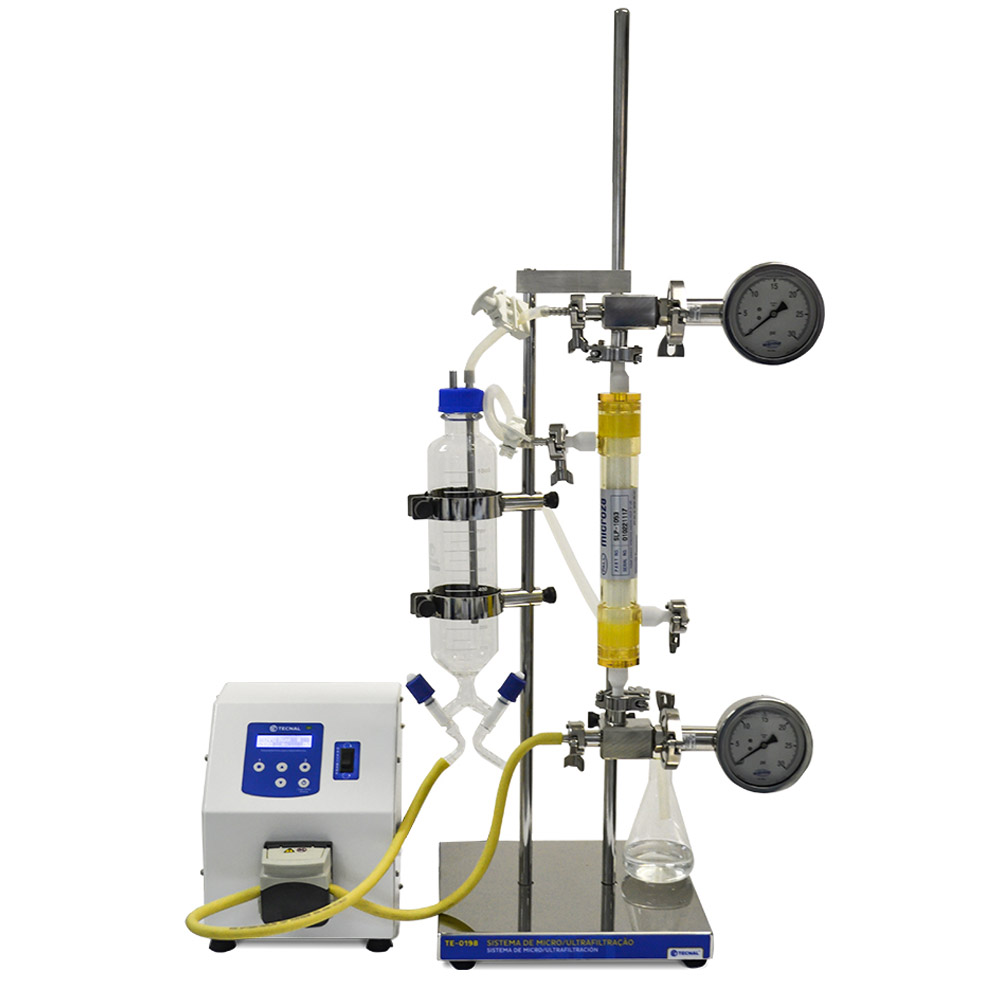

- Developed for filamentous fungi and other microorganisms

- Patented dimensions that maximize oxygen transfer

- Work flexibility using Air-Lift agitation (flow director) or bubble column

- Ideal for establishing protocols and initial studies with filamentous fungi

- Gain in biomass productivity and efficiency due to automation of control and asepsis during the cultivation process

- Study of the nutritional composition metabolism and biochemistry of fungi and other microorganisms.

- It comes with: 6 absolute air filters with a porosity of 0.22 micrometers

- Agitation: Removable baffle with 4 blades at 90º in 316L steel

- Controller: Sampling system: syringe-based, contamination-free with autoclavable reservoir

- Other entries: Bubble pneumatic - Air-Lift (flow director) or bubble column

- Cover entries: Well for Pt-100; Well for pH sensor (PG13.5); Well for O2 sensor (PG13.5); 1 extra entry (PG13.5); 1 single inlet for adding acid; 1 Triple entry (for addition of base, antifoam and nutrients); Adjustable level sensor (liquid/foam); Adjustable sampling tube; Septum for inoculum; 316L stainless steel reflux condenser

- Sensors and actuators: According to controller - quoted separately: SENSORS: temperature, redox pH, dO2 (polarographic or optical); dCO2, gaseous O2 and gaseous CO2; BIO-TEC-MG, Gas mixer for O2, CO2, N2 and Air; BIO-TEC-CM, Automatic Mass Flow Meter/Controller; BIO-TEC-ROTAMETRO, Manual flow meter/controller; BIO-TEC-LED, Photoperiod of LEDs; BIO-TEC-BP, Peristaltic pump with ON/OFF control for acid, base and antifoam dosage; BIO-TEC-BP-ROT, Peristaltic pump with variable flow control for nutrient dosing; NOBREAK sinusoidal 2.4 KVA; DA-1000-REACTOR, Air Compressor, oil-free with noise damper.

- Software: Control and operation software with pages for configuration, calibration, visualization of graphs, operation, preparation of recipes and issue of reports (process data); Shake/rotation control loop; Foam level control mesh; Pressure control mesh; Temperature Control Mesh; pH control mesh; Dissolved oxygen control loop with cascade, depending on the actuators purchased; Monitoring of oxygen and carbon dioxide gas. Magnification for several variables, such as redox, conductivity, PAR radiation, among others upon customer request.

- Cover: 316L stainless steel; 316L stainless steel bakelite knobs; Seal: FDA approved Viton O-ring

- Vessel type: 316L stainless steel double wall (jacketed)

- Vessel type: Pneumatic: AIRLIFT and Microalgae - Total volumes: 3.0L/7.5L/15L/customizable; Useful volumes 2.0L/5.0L /10L/customizable

Diogo Patrini Cerqueira

diogo.cerqueira@tecnal.com.br

diogo.cerqueira@tecnal.com.br