CAMERA FOR TESTING THE APPLICATION OF AGRICULTURAL

CAMERA FOR TESTING THE APPLICATION OF AGRICULTURAL

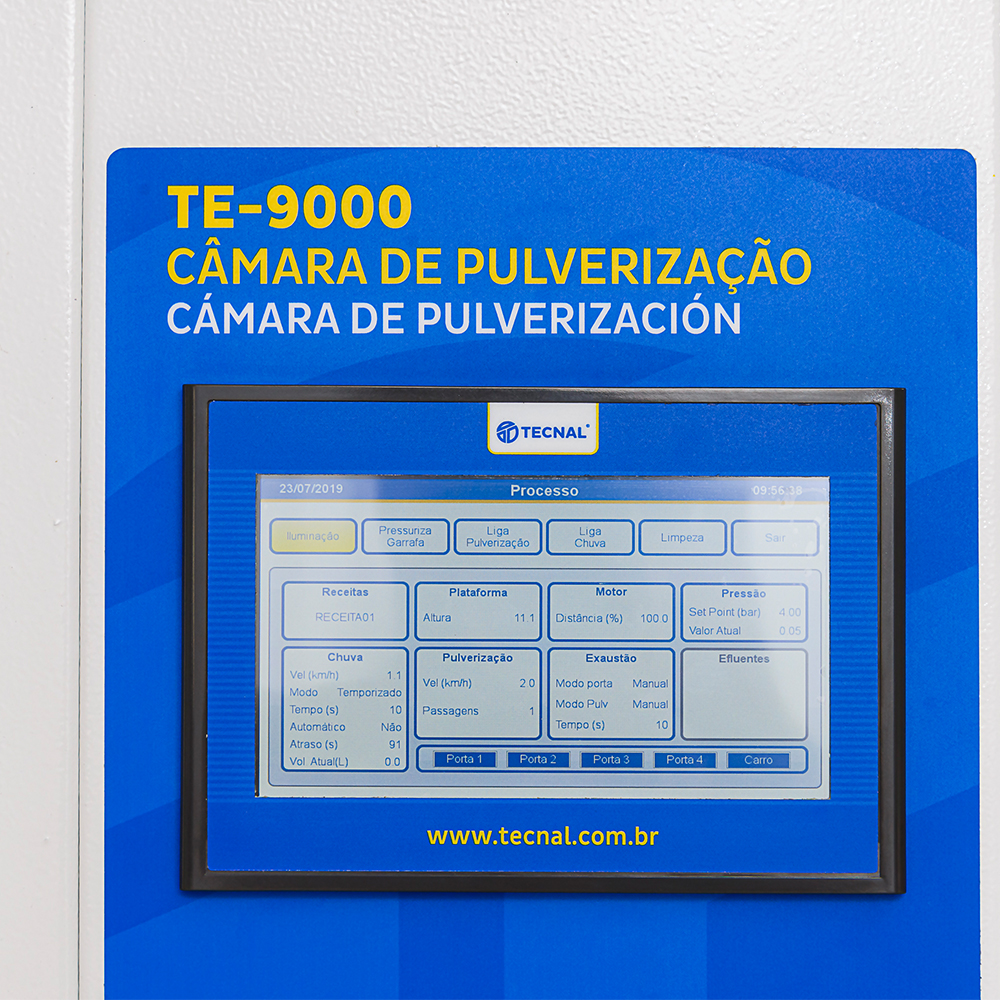

TE-9000

Tecnal presents the TE-9000, its new chamber for spray testing with uniformity of application in a controlled environment. With it, you can run trials with different products, such as pesticides, adjuvants and liquid fertilizers/biofertilizers. Browse the product description for more details.

Sugar & Ethanol

Sugar & Ethanol

Food, Beverage & Animal Nutrition

Food, Beverage & Animal Nutrition

Environmental, Waters & Effluents

Environmental, Waters & Effluents

Plant & Soil Science

Plant & Soil Science

Pharmaceutical & Cosmetics

Pharmaceutical & Cosmetics

Microbiology & Biotechnology

Microbiology & Biotechnology

Chemistry & Petrochemicals

Chemistry & Petrochemicals

VÍDEOS

- Prevents drift loss, increasing spray efficiency and uniformity

- Automated spraying with configurable jet speed and pressure, eliminating sources of variation typical of manual spraying

- Possibility to perform tests with different types of spray nozzles quickly and accurately

- User autonomy to perform the test at any time, not conditioning it to desired environmental conditions

- Performs accurate applications, without overlapping samples

- Automatic adjustment of tray height, allowing tests with plants of different sizes

- It is not necessary for the operator to use PPE (personal protection equipment), simplifying the process and avoiding exposure to toxic substances or products

- Internal lighting system that allows viewing during the test

- Exhaust system that guarantees user safety, especially when tests are carried out with toxic products

- The door security sensor is also a security item: in case the doors are opened, the system takes action and immediately stops all camera operation

- Stainless steel internal coating, which prevents corrosion and provides high resistance and longer service life to the equipment

- The HMI (Human-Machine Interface) is totally intuitive and in Portuguese, which allows you to customize different details of the test you will run

- Rain simulator, with speed and water flow configuration, to be used after the application of the products to assess the level of product loss, simulating a real situation in the field

- System for changing bottles between tests is extremely fast and easy, optimizing the user time during product testing

- Possibility of carrying out spray tests with small volumes of product, making the tests more economical

- Data logger that allows the storage of all parameters configured for the test in the form of a report, being easily collected with a pen drive or via RS232 communication.

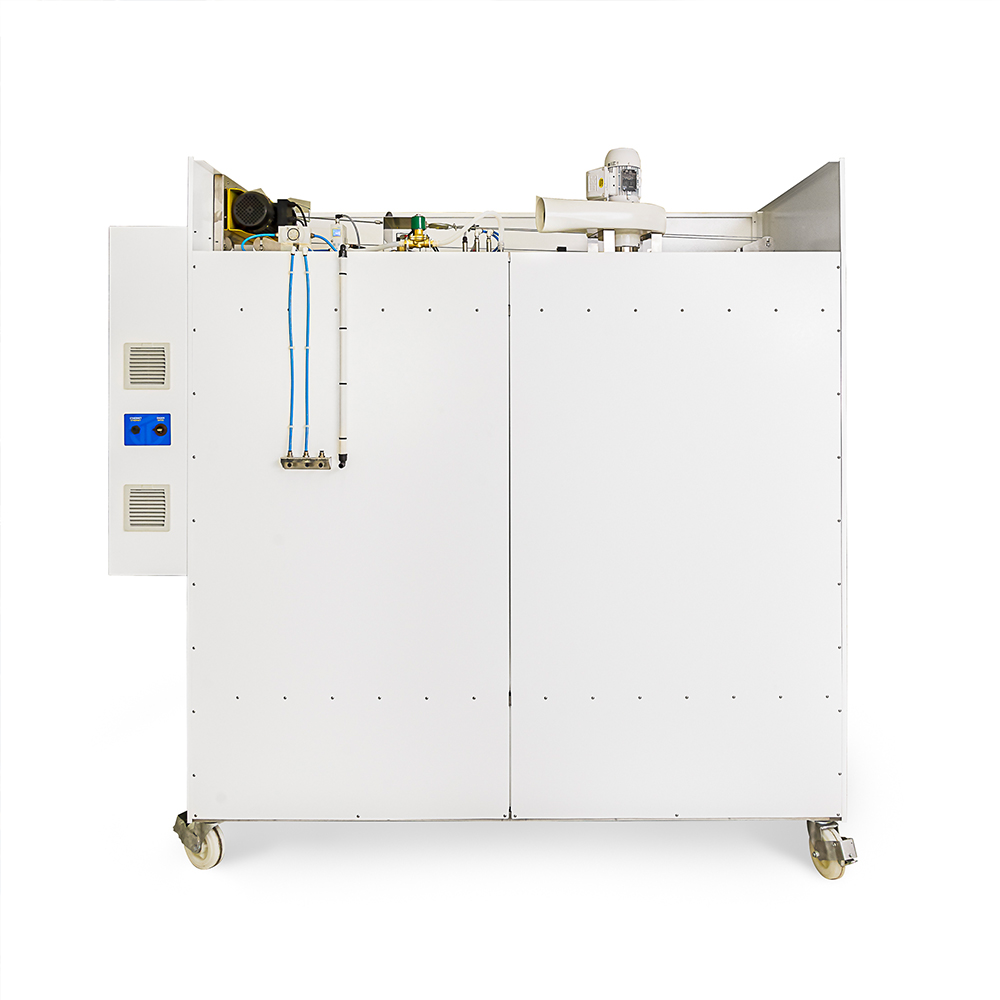

- *** Equipment produced in AISI 304 stainless steel. External components made of carbon steel coated with electrostatic paint

- External dimensions: 2355 (W) x 2290 (H) x 1020 +100* (D)

- Internal dimensions: 1980 (W) x 1540 (H) x 900 (D)

- Total volume: 2740 Liters

- Maximum spray speed: Up to 8 km/h

- Maximum load capacity: Up to 50 kg

- *** Automatic chamber washing system after use

- *** Sample tray lifting via HMI

- *** Fluorescent indoor lighting

- *** Caster system for movement with lock

- Air inlet: through cylinder or compressor (max. 11 bar)

- Equipment control: through HMI, enabling to trigger and/or regulate the following parameters: Exhaust (auto, manual, off), Rain (on, off, Wash (on, off), Sprayer configuration (spray speed, sprayer displacement , spray pressure, recipe), Platform (up, down), lamp (on, off) Automatic exhaustion, through sirocco

- door: 4-leaf sliding

- Security sensor: on 4 doors, turning off spraying in case of door opening

- *** Remote access to equipment via cable

- Optional :

- *** Rain simulator

- *** Rain schedule (eg after two hours of spraying pesticide, simulate rain to study product washing)

- *** Waste collection box

- Benefits and advantages: Its exhaust system guarantees user safety, especially when tests are carried out with toxic products; The TE-9000 has an internal lighting system, which allows full monitoring of the process; The door security sensor is also a security item: in case the doors are opened, the system comes into action and immediately stops all camera operation; Forget about manual dosing and testing directly in the field or in greenhouses. With the TE-9000 you have greater control of the analyzes and with total security as they are carried out in a controlled environment; The TE-9000 is produced to have a high strength and longer service life, so it has an internal stainless steel lining to prevent corrosion; The HMI (Human-Machine Interface) is totally intuitive and in Portuguese, which allows you to customize different details of the test you will run; You can, for example, control the spray speed, precisely set the spray pressure to control the application speed, as well as automatically adjust the tray height, enabling tests on plants of different sizes; Tecnal developed for the TE-9000 a rain simulator, with speed and water flow configuration, to be used after the application of the products to test the level of product loss, simulating a real situation in the field; The system for changing bottles between tests is extremely fast and easy, optimizing the user time during product testing; In addition, the TE-9000 also makes testing more economical, as it is possible to carry out spray tests with small volumes, optimizing the investment; It also has a logger with data from the spraying performed, which can be exported as a report on a pendrive or via RS232 communication.

Tecnal offers solutions in equipment for laboratories in various segments of activity, focused on the proper functioning of products, ease of use and high accuracy of results!

Anderson Luiz dos Santos

anderson.santos@tecnal.com.br

anderson.santos@tecnal.com.br