AIRLIFT BIOREACTOR FOR MICROALGAE

AIRLIFT BIOREACTOR FOR MICROALGAE

TEC-BIO-P-3,0-AIR-LIFT-RM

Fermentations and Bioprocesses;

Microalgae and cyanobacteria cultures;

2G Biomass, Biofuels and Ethanol;

Production of compounds (vitamins, proteins, antioxidant lipids, etc.);

Biological Control, Bioinoculants and Biofertilizers;

Bioremediation and Waste Treatment.

Sugar & Ethanol

Sugar & Ethanol

Food, Beverage & Animal Nutrition

Food, Beverage & Animal Nutrition

Environmental, Waters & Effluents

Environmental, Waters & Effluents

Plant & Soil Science

Plant & Soil Science

Pharmaceutical & Cosmetics

Pharmaceutical & Cosmetics

Microbiology & Biotechnology

Microbiology & Biotechnology

Chemistry & Petrochemicals

Chemistry & Petrochemicals

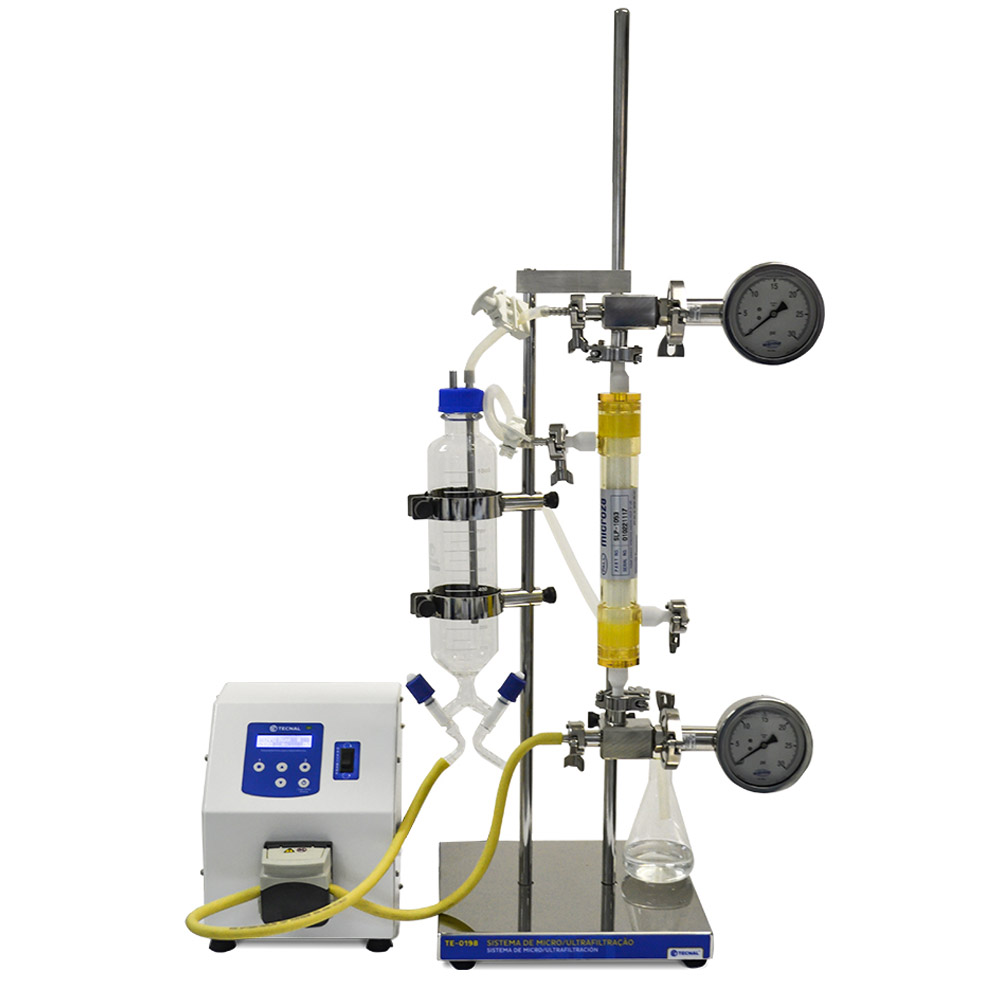

- Developed for Microalgae and Cyanobacteria due to the Photoperiod system

- It can be used for filamentous fungi and other microorganisms

- Patented dimensions that maximize oxygen transfer

- Work flexibility, using Air-Lift agitation (flow director) or bubble column

- Ideal for establishing protocols and initial studies with microalgae

- Gain in biomass, productivity and efficiency due to automation of control and asepsis during the cultivation process

- Study of the nutritional composition, metabolism and biochemistry of microalgae.

- Agitation: Pneumatics by directional movement of the upward flow of gas (usually air)

- Vessel dimensions: D=220mm x H=470mm (without condenser)

- Cover entries: Well for temperature, pH, dO2, dCO2 or spectroradiometer sensors. 4 single inputs for addition of acid, base, antifoam and nutrients, adjustable foam level sensor, adjustable sampling output, 316L stainless steel septum and reflux condenser

- Sampling system: Syringe-based, contamination-free with autoclavable reservoir

- Cover: 316L stainless steel with 304 stainless steel knob closure

- Work temperature: Coolant +7°C to 60°C

- Thermostatization: Through water jacket on 316L stainless steel base

- Reaction vessel: Borosilicate glass with 316L stainless steel jacketed base

- Seal: FDA Approved Viton O-ring

- Total volume: 3.0 liters

- Useful volume: 2.0 liters

Diogo Patrini Cerqueira

diogo.cerqueira@tecnal.com.br

diogo.cerqueira@tecnal.com.br